Your Core Is Our Core Business: Tailored In-House Solutions Across Diverse Markets

March 27, 2024

Reducing Carbon Footprint in the Packaging Industry

April 16, 2024Compressive Resistance of Northrich ANGLEGUARD™

Elevating Protection, Embracing Sustainability

In the quest for the most reliable edge protector, one that ensures safe transportation and storage of goods without compromise, our customers seek not just efficacy but sustainability. To meet this demand, we embarked on an in-depth study with Micom Laboratories Inc., an independent lab renowned for its meticulous testing and material expertise. This collaboration was aimed at evaluating the performance and integrity of Northrich ANGLEGUARD™ Edge Protector under rigorous lab conditions, showcasing our commitment to delivering solutions that stand the test of time and the elements.

Testing Procedure

To ascertain the Angleguard's performance, we adhered to the stringent ASTM D642 standard method, leveraging Micom Laboratories' expertise in product and material testing. Each Angleguard™ was precisely positioned on the testing machine to ensure even distribution of force, crucial for accurate compressive resistance measurement. The test involved applying a load at a consistent speed of 0.5 inches/min, with the failure point meticulously recorded, providing a clear measure of the product's strength in pound-force (lbf).

Samples Tested

Our comprehensive analysis spanned three Angleguard™ lengths: 20, 40, and 60 inches. For each length, we delved into four thicknesses—120, 160, 200, and 225 pt, across three leg widths: 2x2, 2.5x2.5, and 3x3 inches. This extensive range was strategically selected to mirror the diverse requirements of our clients, ensuring the data collected was both relevant and robust. The variation in lengths allows us to evaluate the Angleguard's performance across a spectrum of potential applications, offering valuable insights into its versatility and efficacy.

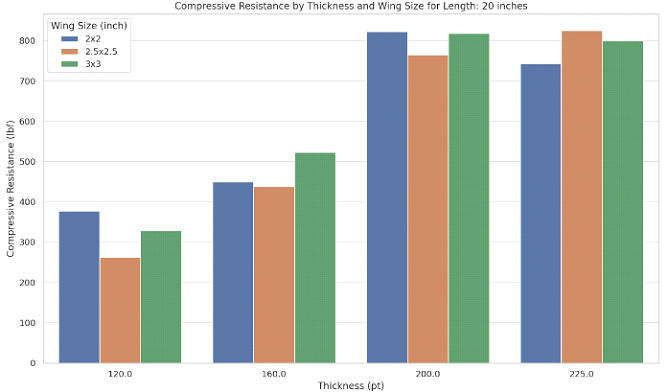

20’’ AngleGuard™

40’’ AngleGuard™

60’’ AngleGuard™

Results and Conclusions

Thickness as a Key Factor

Across all lengths and leg widths, a direct correlation between thickness and compressive resistance was observed. Thicker Angleguard™ consistently outperformed their thinner counterparts, highlighting the importance of material robustness in packaging protection.

The Influence of Length and Leg width

While longer Angleguard™ demonstrated varying degrees of compressive resistance, the size of the legs notably enhanced the product's strength. Larger legs effectively distributed force, amplifying the structural integrity of the Angleguard™.

Optimal Configurations for Maximum Resistance

The pinnacle of performance was achieved with Angleguard™ featuring a thickness of 225 pt and a leg width of 3x3 inches, offering unparalleled protection against compressive forces.

A Harmonious Balance

The testing underscored the significance of balancing thickness, length, and leg width according to specific needs. This equilibrium ensures optimal performance, marrying material efficiency with the utmost protection.

Specific Observations

At a 20-inch length, there's a significant increase in compressive resistance with increased thickness for all leg widths.

The patterns observed for 40 and 60-inch lengths suggest that while thickness and leg width are critical, other factors (like material composition) also significantly impact the compressive resistance.

These insights suggest that when selecting or designing Angleguard™ for specific uses, considering the interplay between thickness, length, and leg width is crucial. For situations demanding the utmost strength, prioritizing maximum thickness and leg width is advisable. However, when constraints like material cost or space are paramount, optimizing based on specific load requirements and balancing the factors of length and thickness will yield the best results.

Compressive resistance of Angleguard ™

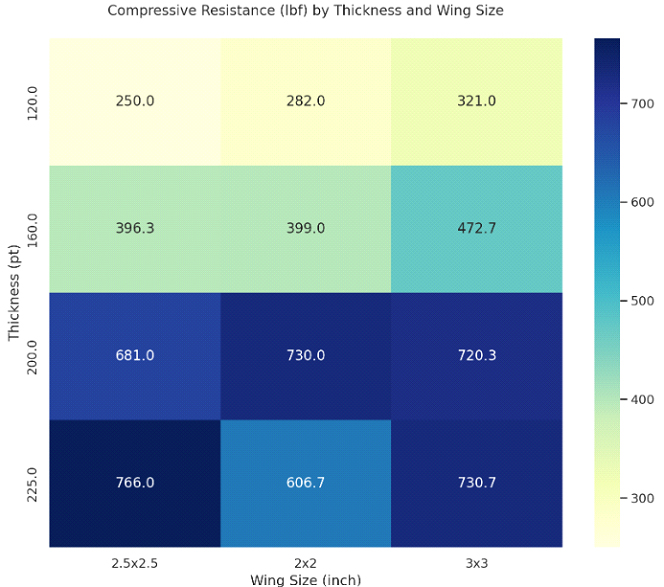

Here's a heatmap showing the compressive resistance of Angleguard™ based on their thickness and leg width. Each cell represents the average compressive resistance for a given combination, allowing you to easily compare how these two factors interact to affect performance. This visual representation highlights the trends and patterns discussed earlier, showing that thicker and larger-leged Angleguard™ tend to offer higher compressive resistance.

As illustrated, the graph clearly demonstrates the relationship between thickness, leg width, and compressive resistance, offering an easy comparison of the effectiveness of different leg widths at enhancing the compressive strength of Angleguard™.

Disclaimer

The findings and conclusions presented herein are based on an average of three tests per sample configuration to ensure accuracy and reliability. However, it is important to note that actual performance can vary due to several factors. The composition of the Angleguard™ (Bill of Materials) plays a significant role in its compressive resistance and overall performance. Additionally, storage conditions including time, temperature, and moisture levels can significantly impact the Angleguard's effectiveness. We recommend considering these factors when evaluating the suitability of the Angleguard™ Edge Protector for specific applications, to ensure optimal performance and protection.