Celebrating Northrich’s Recognition as a Top Pulp and Paper Manufacturer and Our Commitment to Excellence

December 9, 2023

Investing in the Future: How Our New Palletizer Strengthens Our Competitiveness

February 29, 2024A Comprehensive Guide to Paperboard Materials

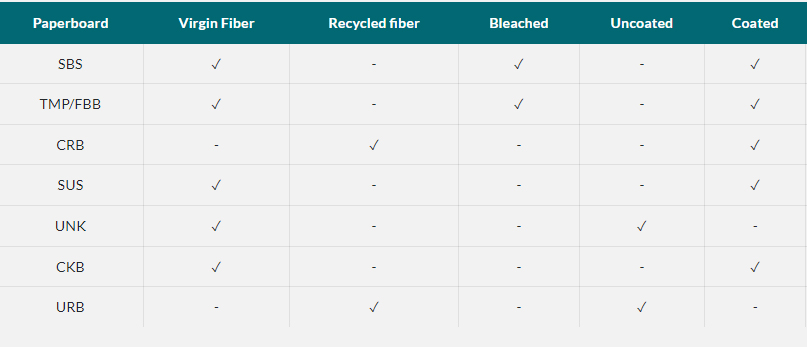

In the ever-evolving world of packaging, the shift towards sustainability and efficiency has led to a significant rise in the demand for paper-based packaging solutions. These solutions, crafted from various paperboard materials, are at the forefront of combining environmental responsibility with the high-quality requirements of modern packaging needs. This article delves into the characteristics, applications, and suppliers of key paperboard materials used in paper-based packaging solutions, shedding light on their unique properties and how they cater to diverse packaging demands. From the pristine whiteness and smoothness of Solid Bleached Sulfate (SBS) to the robust and eco-friendly attributes of Coated Recycled Board (CRB) and beyond, we explore the nuances that make each material suitable for specific packaging applications. Join us as we navigate through the landscape of paperboard materials, highlighting their contributions to the packaging industry's move towards a more sustainable and innovative future.

Recycled Fiber

Coated Recycled board

CRB, CCNB, CCWB, Duplex, LWC…

Globally, CRB—or CCNB (clay-coated newsback)—dominates as a preferred material for low-cost paper-based packaging solutions when recycled content is desired or mandated. Made from a blend of recycled fibers including newsprint, old corrugated containers, and mixed secondary paper, CRB features up to eight layers, with the top ply consisting of bleached or semi-bleached fibers. Its manufacture employs various machines, such as fourdrinier, cylinder, and hybrid forming systems.

CRB stands out for its multi-purpose packaging applications, offering a one-direction stiffness advantage despite not prioritizing tear strength and premium print quality. Notably, CRB versions with enhanced wet strength are available for refrigerated and frozen packaging needs. Key North American suppliers include Graphic Packaging (Conquest), Westrock (Renew), and Paperworks (Masterworks).

The Coated Recycled Board (CRB) market in North America is witnessing a significant shift with the increasing influx of overseas CRB options. These international offerings are catching the attention of North American consumers and businesses alike, primarily due to their competitive pricing. Overseas CRB brings to the table a compelling alternative to domestically produced paperboard, challenging local suppliers to innovate further in terms of pricing strategies and product offerings.

Uncoated recycled board

URB, Bending Chip, Chipboard

URB, or Uncoated Recycled Paperboard, commonly known as Chipboard, is a testament to the packaging industry's commitment to sustainability. Made entirely from recycled fibers, URB features a smooth, uncoated surface on both sides, with its color varying based on the specific recycled materials used. This variance adds to the uniqueness of each piece, providing a distinct appearance that can be leveraged for various packaging applications.

With primary North American suppliers including Cascades, Kruger, White Birch, Long Falls Paperboard, Greif, and Sonoco, URB stands as a versatile and eco-friendly option for businesses looking to minimize their environmental footprint while still achieving high-quality packaging outcomes.

Virgin Fiber

Solid Bleached Sulfate (SBS)

In North America, SBS stands as a premium choice for paper-based packaging solutions. Derived from predominantly hardwood, first-generation, chemically pulped fibers, this material undergoes a thorough bleaching process before being refined and shaped into a single ply on fourdrinier-type paperboard machines. The result is a material that boasts a uniform white appearance, both on its surface and throughout its structure. Its relatively short hardwood fibers are coated and polished, providing an exceptionally smooth print surface ideal for high-quality imaging across various printing techniques such as offset, flexography, and gravure.

SBS excels in applications requiring embossing, hot foil stamping, creasing, and gluing, thanks to its clean cutting attributes and robust internal and surface strength properties. Although not known for tear strength, SBS offers commendable stiffness and compression strength, making it suitable for high-speed printing processes with tacky oil-based lithographic inks. Its hygienic qualities, coupled with an absence of odor and taste, render it perfect for flavor-sensitive products such as cigarettes, pharmaceuticals, chocolates, and cosmetics. Despite its higher cost relative to other paperboard options, SBS's suitability for refrigerated and frozen applications underscores its versatility. Major North American suppliers include International Paper (IP-Everest), Westrock (Printkote), Georgia Pacific (GP-Masterprint), and Clearwater (Candesce).

Folding Box Board (FBB, TMP)

FBB, also known as CTMP or TMP, is characterized by its construction, which includes middle layers of mechanical pulp flanked by outer layers of chemical pulp. The top chemical pulp layer is bleached and pigment coated, while the paperboard's back displays a cream (manila) color, influenced by the translucent nature of the bleached or unbleached chemical pulp back layer. This structure not only ensures the paperboard's virgin fiber purity for product safety but also creates a strong, stiff sheet with low density and high stiffness.

The fully coated grades of FBB enhance printing and visual impact, making it a favored choice in Europe and Asia. Leading suppliers in these regions include Rayonier (Kallima), Metsä Board (Pro FBB Bright), Stora Enso (Tambrite), and APP (Zenith).

Solid Unbleached Sulfate (SUS)

Solid Unbleached Sulfate, also known as SUS or Clay Natural Kraft (CNK), is a robust paperboard material celebrated for its superior strength and tear resistance. This paperboard is produced from a blend containing at least 80 percent virgin unbleached, natural wood pulp, mostly utilizing longer softwood (pine) fibers to fortify its strength. To slightly enhance the surface's smoothness, a small amount of hardwood fibers is incorporated into the top layer. Its surface is whitened through the application of an extremely opaque, titanium-based coating, optimizing it for printing applications.

SUS's inherent moisture resistance makes it a prime choice for packaging solutions intended for refrigerated and frozen environments, exemplifying its versatility in various applications. In North America, Graphic Packaging and Westrock are leading suppliers, offering high-quality SUS for diverse packaging needs.

UNK Uncoated natural kraft (KraftPak)

Uncoated Natural Kraft, commonly referred to by the brand name KraftPak, is another essential player in the realm of paper-based packaging solutions. This material is crafted on a fourdrinier-type paperboard machine, forming two distinct layers. The top layer is enriched with hardwood fibers to slightly improve the smoothness of the surface, while maintaining a strong, lightweight, and unbleached quality. Despite its lack of coating, which affects graphic reproduction compared to coated alternatives, its natural, earth-tone appearance provides a unique aesthetic that designers often leverage creatively.

KraftPak, primarily supplied by Kapstone Charleston Kraft (now part of Westrock), stands out for its strength, cleanliness, and efficient use of fiber, making it a sustainable choice for packaging applications that demand durability and environmental consideration.

Coated Kraft Back (CKB)

The Coated Kraft Back (CKB) material is making significant inroads into the North American market, driven by its ability to offer cost-effective yet high-quality packaging solutions amidst stiff competition. CKB's innovative structure, comprising five layers with a middle CTMP layer, delivers exceptional stiffness. This allows for the use of lower grammage without sacrificing the packaging's structural integrity. The top layer's double blade coating enhances printability, ensuring that CKB is both visually appealing and functionally robust.

CKB's chemical and microbiological purity makes it suitable for a wide range of consumer packs, especially for packaging dry, chilled, and frozen foods, as well as luxury items like chocolate, wine, and spirits. Its strength and lightweight characteristics also make it ideal for multipacks, which are convenient for consumers to purchase, carry, open, and recycle. Stora Enso and CMPC are among the primary suppliers in Europe and South America, respectively, highlighting the material's growing popularity across continents.

About the Author

Richard Normandin

Richard Normandin is a visionary leader in paperboard protective packaging, renowned for integrating sustainability and ethical practices in his work. His dynamic approach and strategic insight have pioneered eco-friendly packaging solutions, reflecting his commitment to environmental stewardship and ethical business practices. A champion of innovation and customer service, Richard continues to lead the industry towards a greener and more responsible future.